Ensuring Purity and Safety

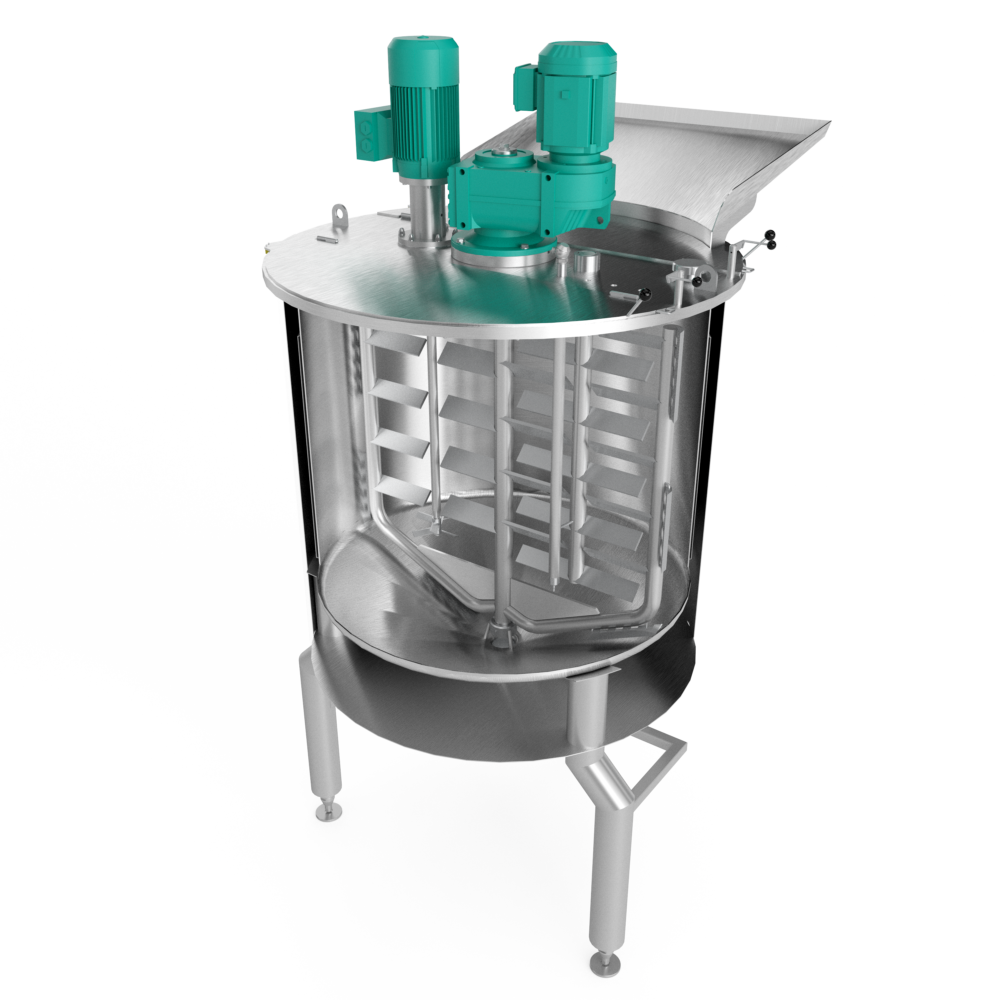

A Sterile Mixing Vessel is essential in pharmaceutical, chemical, beverage, and cosmetics industries for contamination-free mixing. Made from high-quality stainless steel, it's designed for easy sterilization, temperature control, and thorough blending.

Features include:

• CIP and SIP capabilities

• Sanitary fittings and smooth interior surfaces

• Compliance with cGMP, FDA, and CE standards

Applications:

• Pharmaceuticals: Injectables, oral liquids, Ointments, etc,

• Chemicals: PVC /CPVC Solvent, Epoxy Adhesive etc.

• Beverages: Juice, Smoothies, Flavoured milks, etc.

• Cosmetics: Perfume, Body lotion etc,

• Personal Care: Handwash, Body wash, etc.

Ensure product purity and safety with a Sterile Mixing Vessel.